Dynamic weighing system on a conveyor belt

Weighing and batching with a flow regulator and transmitter.

Requirement

In partnership with STAD, make a weighing and batching system, installed in a dedicated machine for the production of mixtures with a continuous cycle in the ceramics sector.

STAD is an Italian company that designs and manufactures systems, machines and automatic weighing and batching systems. It is a LAUMAS partner for dynamic weighing, especially for the development and production of continuous weighing and batching systems on a conveyor belt and with weight loss from a gravimetric batch blender.

Specifically, the system is used to monitor the continuous feeding of clay and adjust the batching of the additives required for ceramics production, with a constant proportion in relation to the variable flow of clay.

Our solution

For the weighing and batching system we used:

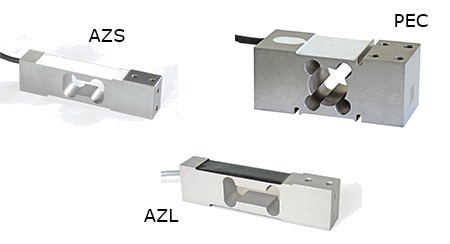

• 2 LAUMAS AZS 100 kg single-point load cells

• 2 LAUMAS AZL 10 kg single-point load cells

• 1 LAUMAS PEC 150 kg single-point load cell

- 1 COBRA 365 weight indicator, with a flow transmitter function

- 1 COBRA 365 weight indicator, with a flow regulator function

- 1 TAIPAN 365 weight indicator, with a flow regulator function

COBRA 365 and TAIPAN 365 are 2 specific components for dynamic weighing, manufactured and developed by LAUMAS to specifications by STAD, which markets them with exclusive rights.

How does it work?

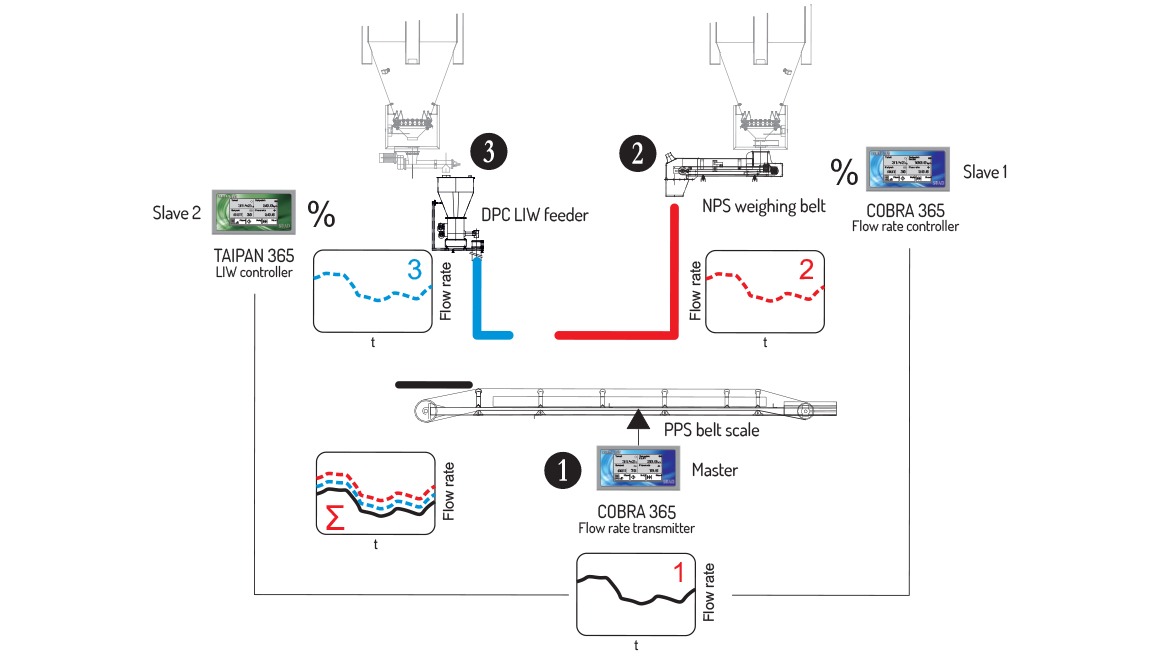

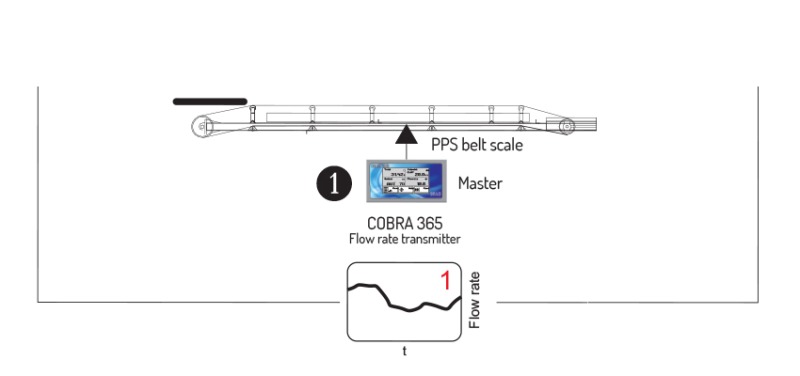

The PPS weighbridge, under which are positioned the 2 AZS load cells, measures the instantaneous flow rate of the clay transported on the belt.

The weighbridge is connected to a COBRA 365 flow transmitter, which calculates the instantaneous flow rate of the clay and performs the role of "master" controller, transmitting the data to the subsequent "slave" controllers.

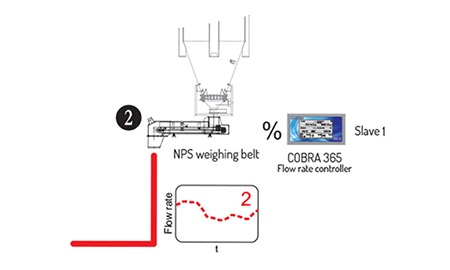

While running on PPS, the clay passes under the NPS weighing belt that acts as a slave percentage batching unit and releases the first additive: manganese dioxide (MnO2).

The NPS weighing belt is connected to a COBRA 365 flow regulator that performs the role of first receiver or "slave 1" controller.

The COBRA 365 "master" transmits the istantaneous flow rate of clay to the COBRA 365 "slave 1" that, according to the data received, regulates the flow rate of additive to be released.

Under the NPS belt are installed 2 AZL load cells, which control the flow rate of the additive released.

It is indeed fundamental for the proportion of clay and MnO2 to remain constant.

Let us suppose that the percentage of MnO2 to be admixed is 1.5% the flow rate of the clay. If the "master" detects that the instantaneous flow rate of clay is 100 ton/h, "slave 1" must regulate the flow rate of MnO2 to 1500 kg/h. If the istantaneous flow rate of clay should drop to 50 ton/h, also the flow rate of MnO2 must in proportion drop to 750 kg/h.

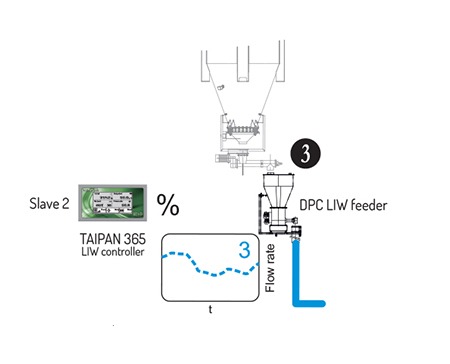

The clay keeps on flowing and goes under the DPC weight-loss batching unit that regulates the batching of the second additive: iron dioxide (FeO2).

The batching unit is combined with the TAIPAN 365 flow regulator and 1 PEC load cell.

TAIPAN 365 performs the role of second receiver or "slave 2", while the PEC load cell, positioned under the DPC batching unit, controls the decrease in weight in the product unloading phase.

The COBRA 365 "master" transmits the data of the instantaneous flow rate of clay also to the TAIPAN 365 "slave 2" regulator, which can then regulate the batching of the additive according to the data received.

In this case, too, the proportion of these 2 ingredients must remain constant.

The added value

- COBRA 365 and TAIPAN 365 communicate with each other in master/slave mode giving life to effective, simple and economical batching systems.

Both models anyway have different fieldbuses to interact also with sophisticated supervision systems via PLC. - The AZS load cells positioned under the PPS weighbridge have a high overload coefficient. This contributes to the robustness of the weighing system and ensures the accuracy of the weighing.

- The combination of these elements permits keeping a constant proportion of additives in relation to the quantity of clay, ensuring a durable and high quality end product.