Monitoring and weighing system on bascule bridge

A weighing system for the Meulestede bridge, in partnership with Althen Sensors & Controls.

Requirement

Althen Sensors & Controls, in partnership with Vandezande, has to build a monitoring and weighing system on the new Meulestede bridge near Ghent, in Belgium.

The bridge is undergoing renovation since it is no longer sufficient for the high flow of traffic and furthermore it is damaged because of many boat accidents.

Althen Sensors & Controls is a Dutch company, a leader in the supply of high-technology industrial sensors.

Vandezande is a Belgian company specialized in water treatment systems and electromechanical equipment for bridges, locks and barrages.

The movable bridge of Meulestede is a "bascule bridge" that is based on the principle of the drawbridge. Its counterweight is underground beneath the road surface and allows it to raise and lower with minimum effort when necessary.

Althen has the job of supplying Vandezande with a long-lasting weight measuring system to correctly balance the counterweight and bridge and ensure accurate weighing in real time.

To function optimally in its daily activity, the counterweight and bridge need to be correctly balanced already in the construction phase. In order to regulate the balancing it is then essential for the system to provide the engineers and the personnel assigned to the work with immediate feedback on the weight monitoring.

Our solution

The 4 load cells are positioned under each corner of the bridge.

The 2 CBLS 500000 kg load cells are positioned on the side of the counterweight and measure up to approximately 340 metric tons of weight each, with a precision of 0.10%.

The 2 CBL 100000 kg load cells instead measure the remaining weight of the bridge resting on the pier opposite the counterweight, with a precision of 0.03%.

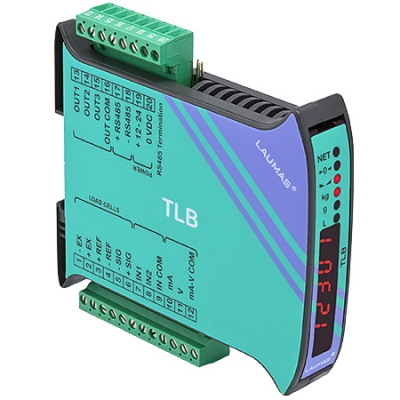

The 4 TLB weight transmitters are each connected to a load cell, while in real time a data logger monitors the load measured individually on each weight sensor.

How does it work?

Whenever the counterweight moves, the bridge raises and compresses the load cells, which send a weight signal to the connected transmitter.

The signal is registered by the data logger, which returns a graph of the weight trend, making monitoring and balancing possible.

In the phase of installation it is essential to balance the bridge and counterweight so that the net weight of the opposite side to the counterweight is almost 0 kg.

During operation, when the counterweight moves, the weight of the opposite side decreases further, becoming less than 0. As a result, since this side is lighter than the side with the counterweight, the bridge raises.

The added value

- CBL and CBLS are compression-low profile load cells, which means that their mechanical structure is greater in windth than in height.

Also for the very high capacity version, the reduced thickness of these weight sensors makes for practical integration under the structure. - The TLB weight transmitter, thanks to its transmission speed, enables immediately identifying and promptly overcoming any imbalance or excessive loads on the bridge.

- The high accuracy of the load cells and the installation of a single weight transmitter for each sensor ensure the precision of the process of weighing and monitoring.

- The easy installation of the components and the technology of the system have increased the efficiency and speed of the bridge construction process, cutting downtime to a minimum.