БЛОГ

Блог

Weighing system on a fertilizer spreader machine for controlling and dosing fertilizer, compost, etc. contained in large polyethylene hoppers. It must opearate in harsh environments and integrate seamlessly with the machinery and control system.

Construction and outfitting of a large boat: load cells, mounting kits, and weight transmitters to verify that the final weight falls within the range established during the design phase.

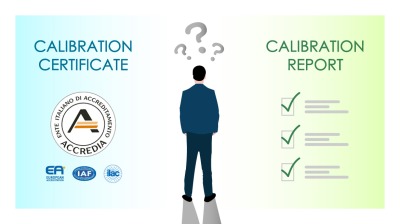

What does it mean to calibrate? What does it mean to adjust What is the difference between adjustment and calibration? Why calibration and adjustment (or fine-tuning) are not synonyms and increase the accuracy of your weighing system.

It is better to request an accredited calibration certificate or a calibration report? Everything you need to know to select the most suitable calibration document for your weighing intrument's needs.

Equipment for an existing machine to collect and, via an App, process the data of the pushing forces during training, and improve match performance.

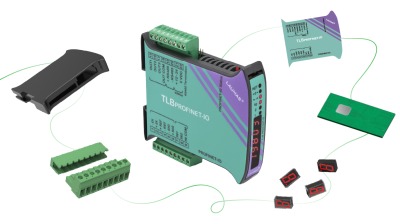

From the printed circuit board to final testing: a journey through the production process of a LAUMAS weight transmitter.

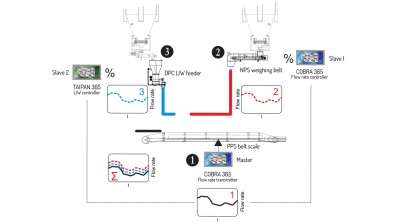

Continuous weighing system for clay on a conveyor belt and additive batching adjustment.

A compact weighing machine, developed by Autentico srl and equipped with a RFID system for double control of production and warehouse logistics.

A long-lasting weight measuring system to correctly balance the counterweight and bridge and ensure accurate weighing in real time.

What are load cells? How do they measure weight force? Let’s find out how weight sensors are made and how they work.

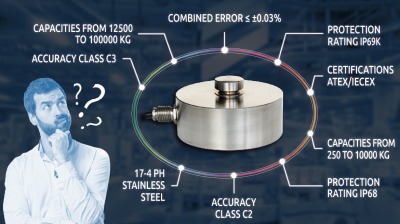

Characteristics and applications of the most common types of load cells.

Analyzing environmental conditions and type of application to select the most suitable load cell.

From the certifications to the technical features of a load cell: let's together analyze all the items on the data sheet.

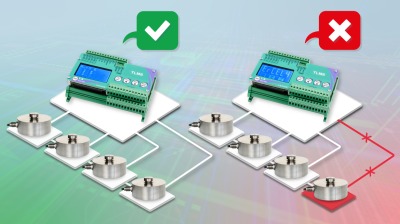

What can be monitored through the diagnostic function, either by the instruments or remotely via PLC?

The construction phases of a load cell: machining the steel workpiece, assembling the mechanism, packing and shipping.

The forkable platform allows you to transport the material, monitor the weight from the driver's cab and print the data directly

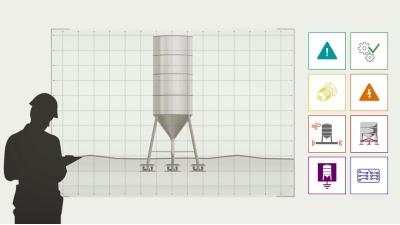

4 solutions to realize precise weighing systems and load limiters on new or existing plants.

How to calibrate a weighing system? The 4 types of zeroing to use depending on the circumstances.

Single-point load cells and intelligent junction boxes: an advantageous, space-saving solution.

Which operating programs can be activated on the LAUMAS W-series weight indicators and how to choose the most suitable one.

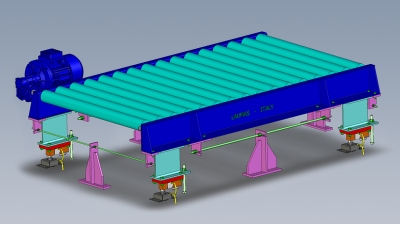

Construction of a plant in the logistics and handling sector, designed for weighing pallets on a motorized roller conveyor.

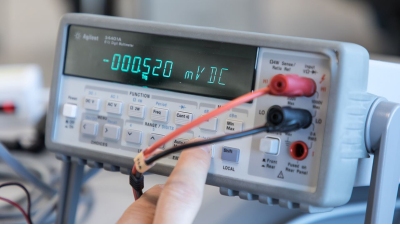

How to check if a load cell is working? Measuring the resistance and voltage of the load cell with a digital multimeter.

How do you install load cells, weight indicators and transmitters in a weighing system correctly?

Integration of weight sensors without external wiring on ACOPOStrak transport rails.

The stories, personalities and strengths of our best-selling weighing components.

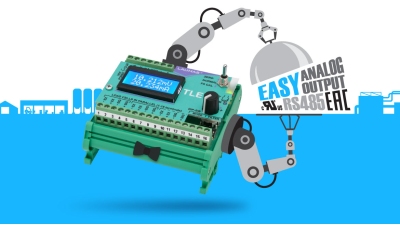

Simple, functional and convenient to configure, it is the most accessible and cost-effective of our weight transmitters.

The weight indicator that relies entirely on its qualities and improves, with a new graphic display and advanced software for weighbridges.

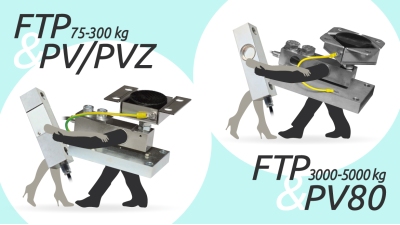

A shear beam or bending beam load cell and as many as 6 mounting kits. In galvanized or stainless steel with self-centering system, also for high capacities.

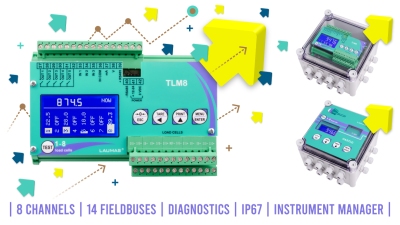

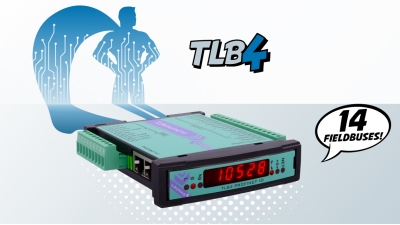

8 independent channels and 14 fieldbuses to monitor, mediate and communicate...also in a 3-A Sanitary Standard certified hygienic version.

5 models, 5 software and 4 types of installation to adapt to any weighing system.

Solid, reliable and made in Italy. A certainty for every weighing system.

The intelligent junction box, in order to have all the advantages and performance of an advanced digital system with analog load cells.

A practical interface with display, keys, and 4 independent measuring channels, for diagnostics and monitoring of the connected load cells.

Practical, compact and functional. It simplifies control operations and is easy to set up.

Together they are the best sellers. Lateral force and anti-tilt constraints ensure simple and safe installation.