TLE: the transmitter at the service of simplicity

Simple, functional and convenient to configure, it is the most accessible and cost-effective of our weight transmitters.

A stylish butler

A trusted butler is professional and knowledgeable and can serve with discretion and helpfulness, just like TLE weight transmitter.

It holds the reins of the weighing systems in which it is installed and accompanies the user toward a new digital dimension with the savoir-faire and dedication of a loyal staff member.

It is the ideal instrument for those who want to tackle the transition to digital gradually and for those who need a transmitter that is easy to manage, basic, but at the same time complete and certified (UL and EAC).

It continues the tradition with a view to the future.

As the heir of the old weight transmitters without a display, it combines tradition and digital innovation, becoming a bridge between the old and the new generation.

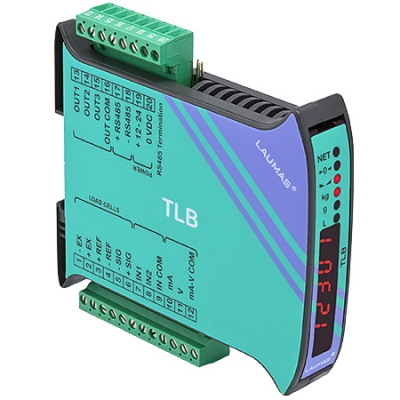

It has at the same time and by default two outputs: one 16-bit analog output and one digital RS485 output (Modbus RTU) to communicate with the PLC.

This allows the customer to choose which one to use, depending on his needs.

Can highlight the most relevant details

The backlit alphanumeric LCD display simultaneously shows the input value in mV of the connected load cells and the output value transformed into mA or V in order to communicate with the PLC.

It is important for the technician who configures the instrument to keep these two values monitored.

Thanks to the zeal of TLE, his work is made easier.

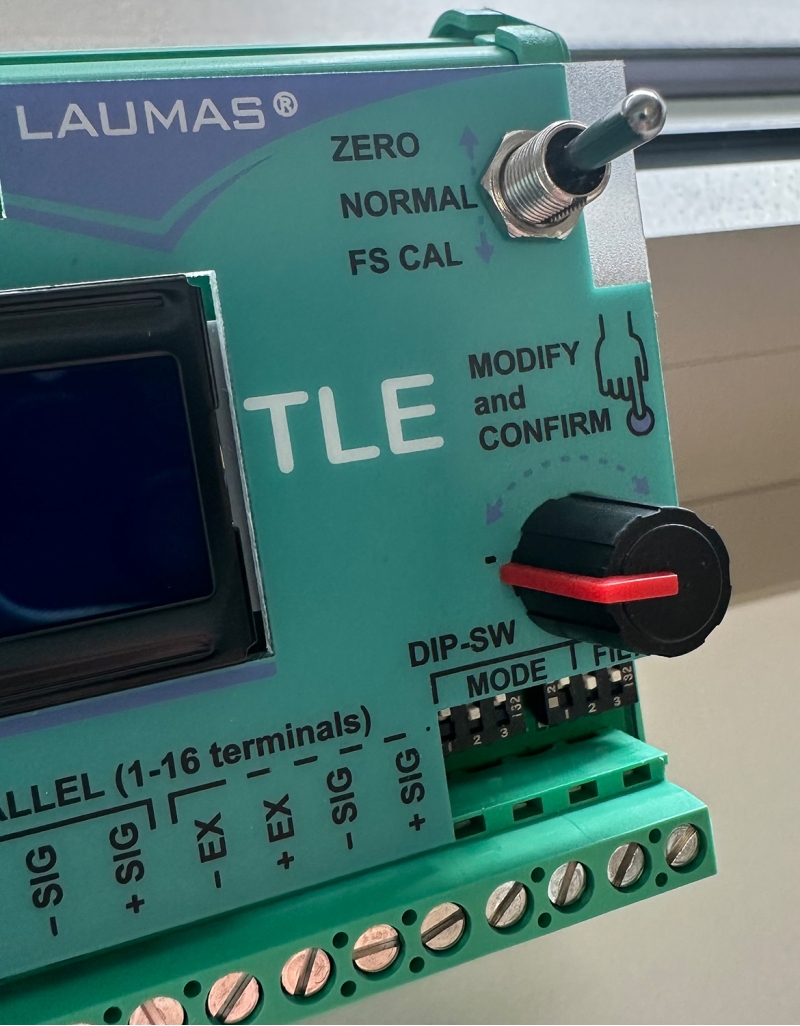

TLE weight transmitter on Omega/DIN rail for back panel mounting.

He has everything under control

A knob encoder and a 3-position selector respectively allow selecting the type of configuration required and performing the calibration by adjusting the value of mA or V.

Configuration is faster, more convenient and intuitive.

In fact, combined together, display and keys allow to easily calibrating the instrument without having to connect a tester (multimeter).

Depending on requirements, both theoretical calibration using the keyboard and real calibration are possible with sample weights.

It is simple and at the service of those who need it most

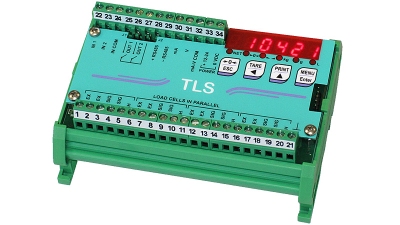

Small and compact, it normally features back panel mounting on an Omega-DIN rail.

In the two versions in box IP67 and IP67 ATEX, it can also be installed in the field near the weighing system.

TLE avoids using a junction box and allows connecting up to 8 load cells in parallel.

Under each group of terminals, it is indeed able to accommodate not just one load cell, but, if necessary, up to two.

Its digital filter reduces the effects of weight fluctuations and has 8 levels that can be set with a signal acquisition frequency of the load cells from 10 to 300 Hz per second.

This allows it to be useful in any system: from mixers (subject to vibration) to conveyor belts.