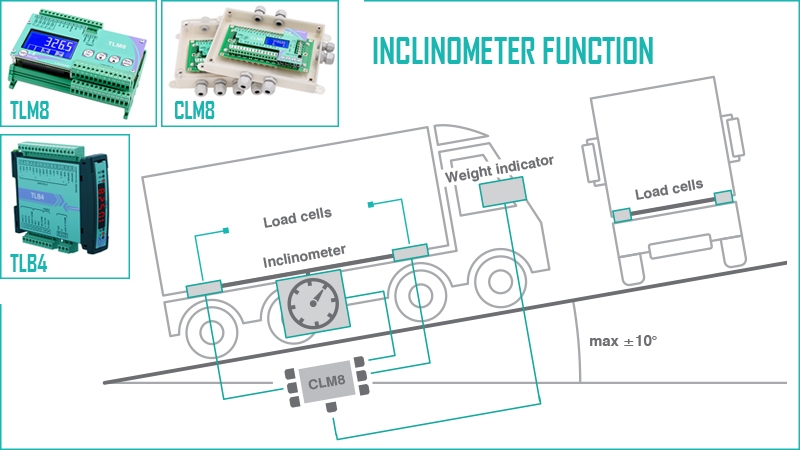

“INCLINOMETER FUNCTION” FOR ON-BOARD WEIGHING SYSTEMS

“INCLINOMETER FUNCTION” FOR ON-BOARD WEIGHING SYSTEMS

THE PROBLEM

In on-board weighing systems and in general in weighing with inclined planes it may happen that the inclination of the structure with respect to the horizontal plane entails variations in the weight values detected.

Now LAUMAS offers a solution that confers maximum precision and reliability, even with inclination variations up to ± 10°.

THE SOLUTION

It is called “Inclinometer Function” and it is the new software available for our multichannel weight transmitters TLM8 and TLB4 and for the intelligent junction box CLM8.

HOW DOES IT WORK?

The LAUMAS instrument is connected, via serial port RS232 or RS485, to an inclinometer applied to the structure to be weighed.

The “inclinometer function” allows the instrument to read the inclination data coming from the sensor and to compensate for the variations of the weight values due to the imperfect horizontality of the system.

The weight correction obtained is also valid for systems approved for legal for trade use (OIML R76 certification).

The inclinometers supported are the NS-15/DPN2-RXG and NS-15/DPG2-RUG models produced by TE Connectivity Sensors, but it is possible to evaluate the compatibility of LAUMAS instruments with different models of inclinometers.

MAIN FUNCTIONS

- Reading and diagnostics of tilt values

- Compensation of weight values variations in the tilt range ± 10° on both X and Y axes

- Calibration procedure to improve the tilt compensation function

- Digital filter to reduce the effects of tilt oscillations

The software allows to use all the inclinometer management functions both from the instrument keyboard and remotely (PLC), via the serial communication interface or fieldbus (MODBUSRTU, MODBUS/TCP, CC-LINK, POWERLINK, PROFINET, DeviceNet, Ethernet/IP, CANopen, SERCOS interface, ETHERNET TCP/IP, EtherCAT).

To learn more about the new inclinometer management software, watch the “ON-BOARD WEIGHING” webinar recording.

Language: English. Duration: 60 minutes. Lecturers: Luca Affanni and Matteo Grisanti.

Agenda:

- Overview of the inclinometer function

- The different applications: practical examples

- The necessary weighing components

- LIVE DEMO: configuration of a weighing system with inclinometer and demonstration of its operation

相关新闻

Our 2025 events

Trade shows: one international and two Italian ones with the latest releases and new product previews

LAUMAS: environmental certification renewed for the next three years

Our commitment extends to the whole production process.

LAUMAS certified CRIBIS Prime Company

Attained the highest level of reliability as a counterpart in a business transaction.