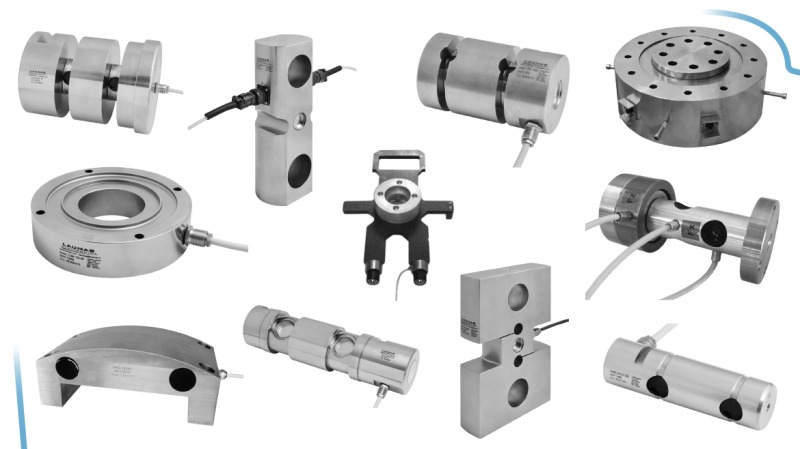

The main types of load cells

Characteristics and applications of the most common types of load cells

Strain gauge load cells, depending on their designed use and application, differ in many features, including shape, method of loading, deformation measurement technology, construction material, capacity, ingress protection rating and many others.

→ Read also: How to choose a load cell? Technical features guide

Let’s see together a round-up of the main types of load cells on the market, specifically focusing on the models offered by LAUMAS.

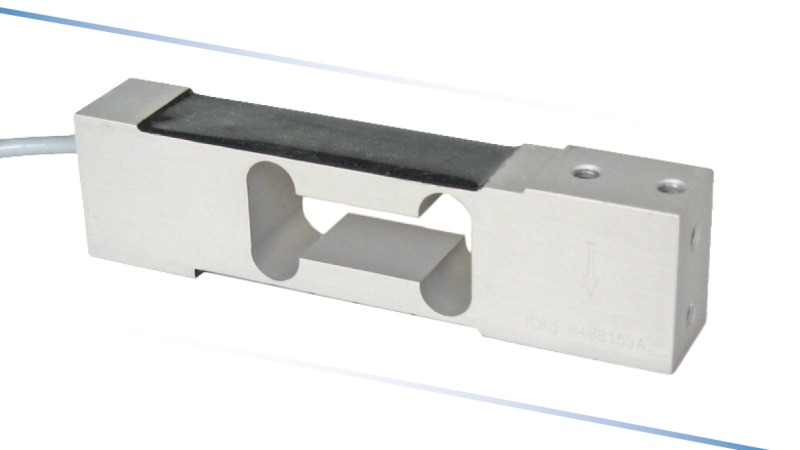

1. Single-point load cells

Single-point load cell, AZL model.

Also known as platform load cells, single-point load cells are ideal when it is not possible to ensure centering the load to be weighed.

They have a cutout in the middle of the mechanical body, which often has a binocular shape.

The cutout is obtained by machine tooling and during commissioning it is fine-tuned so as to give the sensor the characteristics of a symmetric articulated quadrilateral.

This feature allows single-point load cells to ignore the torsions caused by the decentralization of the load and to ensure a correct reading of the weight within its work area.

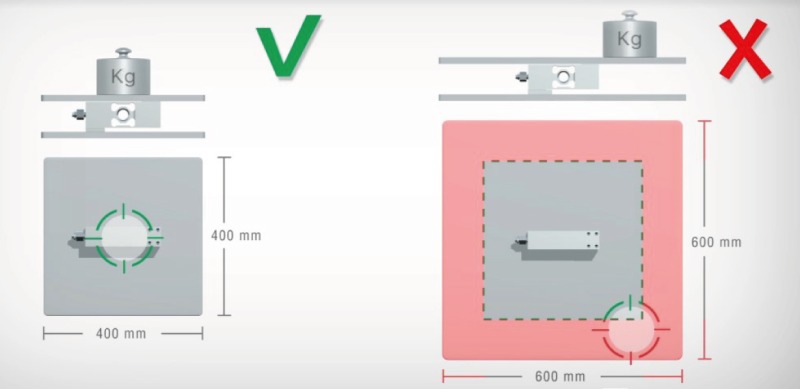

Therefore, set in the middle of a surface of known dimensions, single-point load cells are capable at any point of correctly weighing the weight force applied, within a certain maximum area specified on the data sheet.

The load area varies depending on the model and capacity of the load cell; in the LAUMAS range it goes from a minimum of 150 x 150 mm up to 1200 x 1200 mm.

Single-point load cells are very accurate, also reaching very high accuracy classes such as C9 in accordance with OIML R 60.

Applications

These are very versatile load cells that are used in many applications: platforms, bench scales, small roller conveyors, small tanks and hoppers, filling machines and packing machines, bagging machines, conveyor belts and rollers in tensioning systems.

They are also used in dynamic weighing.

Single-point load cell applied to the middle of a roller conveyor.

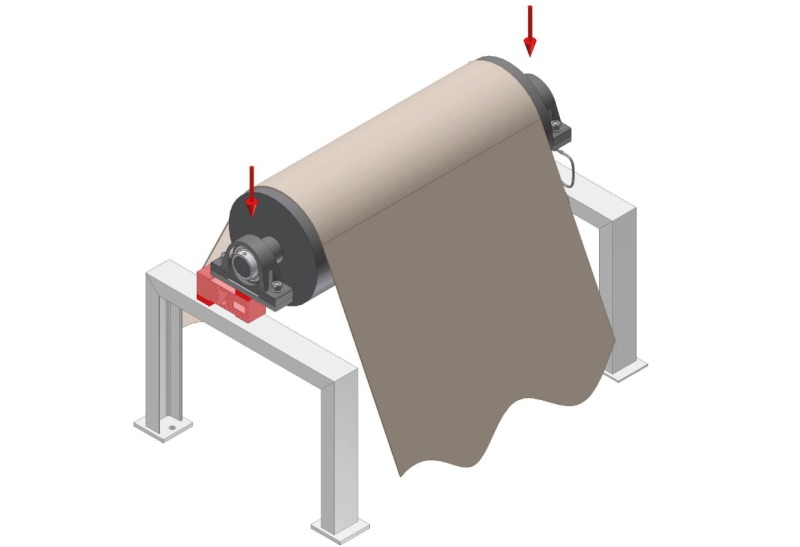

Application on a roller in a tensioning adjustment and measuring system.

Single-point load cells usually work individually.

For reasons of construction, in fact, they have very different rated outputs from each other that, in group work, could create such interference as to compromise accuracy.

However, it should not be ruled out that in certain applications they have to be connected in parallel.

In this case, at the stage of purchase, it is important to inform the vendor about this need since it will be necessary to try and couple load cells with a similar rated output and equalize their output signals.

How to perform equalization?

The LAUMAS range

LAUMAS single-point load cells are chiefly made of aluminum alloy, an advantageous material besides being ideal for many of their most common applications, in which stainless steel is not a necessary requirement.

However, they are also available in stainless steel, both AISI 420 and 17-4 PH.

They have average capacities, from 250 g up to 2000 kg, and reach the C5 accuracy class in accordance with OIML R 60.

The protection rating they can provide (that is their degree of resistance to the ingress of dust and water) is high both for cleaning with more or less strong pressure jets (IP65, IP66 and IP69K) and for immersion with different duration and depth (IP67 and IP68).

2. Compression load cells

Compression-low profile load cell, CBL model.

Compression load cells contain a deformable circular diaphragm, whose thickness varies depending on the capacity of the load cell. The amplitude of the diaphragm ensures that the load cells of the same model all have the same rated output and are all the same as each other.

For this reason they are perfectly interchangeable and replaceable even after some time and suitable for working in groups, connected in parallel in the same weighing system.

The rated output, expressed in mV/V, is the value that the load cell returns when the maximum load is applied, divided by the power supply voltage.

Actually, all the types of load cells generally used in groups always have very similar rated outputs to each other.

At the production stage, in fact, the rated output of the load cells is calibrated by adding the necessary resistors to correct the sensors until reaching the correct output value.

The design of the compression load cells, in particular the top load cylinder with its convex surface, allows them to have a single load point.

As a result, any slight angling of the load will not affect the accuracy of its measurement, since it is always brought back to the middle.

Applications

Compression load cells are generally used in weighing silos, tanks, hoppers, mixers and reactors, even of large dimensions and capacities.

Weighing system under a tank with 4 legs.

The LAUMAS range

LAUMAS compression load cells are made of 17-4 PH or AISI 420 stainless steel. They are therefore very strong load cells.

They have capacities from 200 kg up to 1 000 000 kg and are available with high protection ratings, according to need (IP67 and IP68 or IP69K).

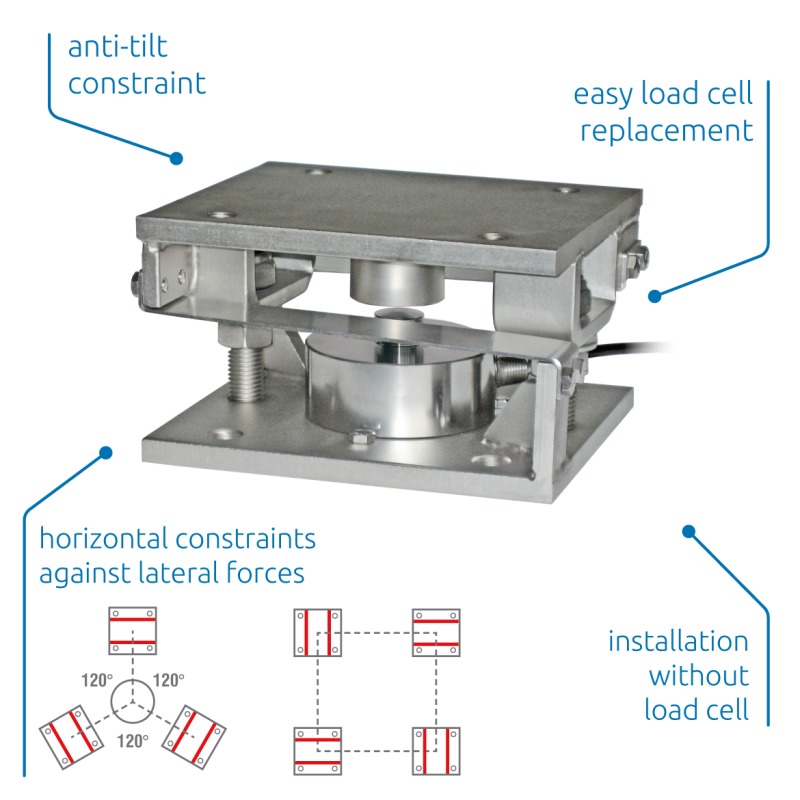

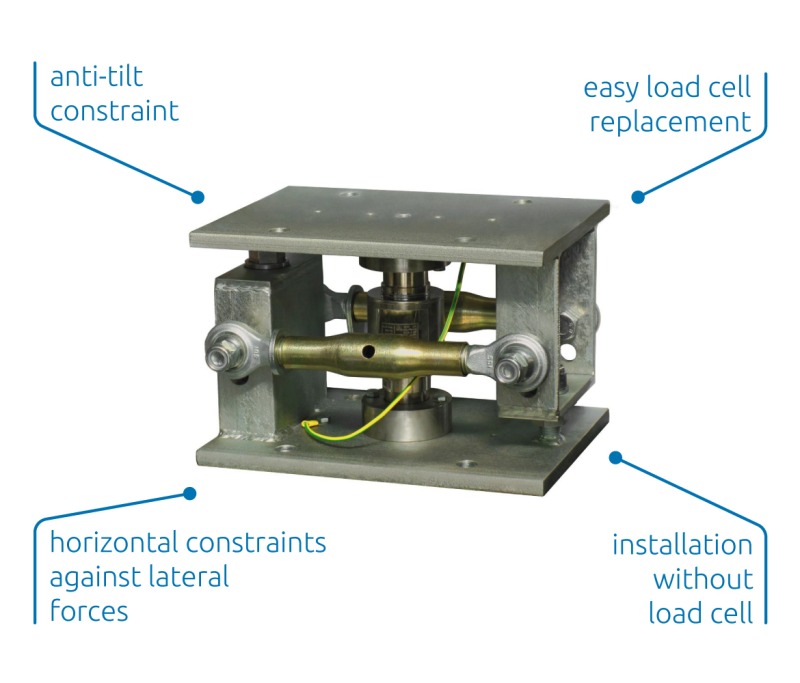

A feature of LAUMAS low-profile compression load cells is their ease of installation.

In fact, they accompany the specifically designed mounting kits to make their installation easier and safer.

▷Easier assembly:

the V series and Z series mounting kits are secured to the structure to be weighed without the load cell inside them. This is easily inserted at a later time, when welding and assembly operations are concluded. In this way there is never any risk of damaging it.

The same ease of installation is also ensured if it is necessary to replace a broken load cell: it is sufficient to remove it from the kit without disassembling it and install an equivalent new load cell.

The V10000 mounting kit.

The PV80CLS and PSCLS mounting kits with anti-tilt constraints.

▷ Safer installation:

all the mounting kits for compression load cells can also act as anti-tilt constraints and against lateral forces, assuring stability for the structure and protecting the load cell from potentially damaging stresses.

3. Load cells for foot

This is a special type of compression load cell, characterized first of all by its ease of installation.

In fact, thanks to its metric threads corresponding to those of the main feet for industrial use, it can easily be installed between the feet of the structure to be weighed, without making any substantial modifications to the system.

The LAUMAS range

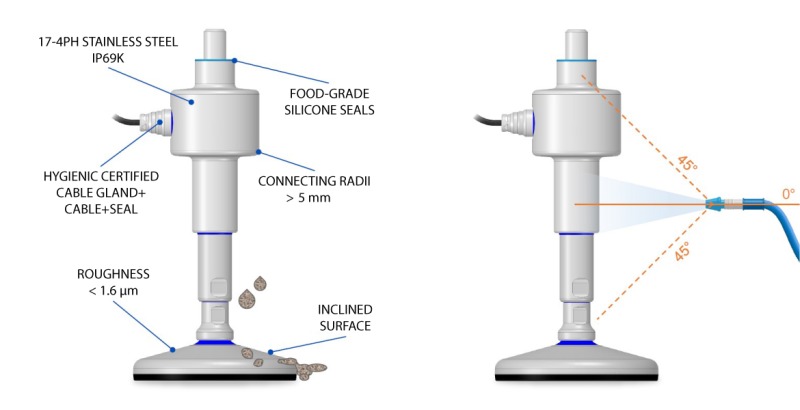

The hygienic load cell for foot, FLC 3A.

The FLC 3A load cell for foot is part of the LAUMAS new hygienic line and is entirely sanitizable and complies with the 3-A Sanitary Standard.

FLC 3A is made of 17-4 PH stainless steel and has an innovative design ensuring load cell hygiene.

It has an IP69K protection rating making it totally dust-proof and waterproof, ideal for applications using high-pressure and high-temperature jets of water.

It has a hygienic cable gland, food contact cable and food-grade silicone seals.

The 3-A Sanitary Standard is an American standard that regulates the design, manufacture and use of hygienic equipment, with the purpose of protecting the end product from the risks connected with contamination and bacterial proliferation.

The certification is voluntary and certifies that the component, in this case the load cell, is constructed in such a way that it can be sanitized and disinfected and not foster the proliferation of bacteria.

The hygienic requirements of the FLC load cell for foot.

A strong point of our load cell for foot is precisely its ease of assembly. Its installation is fast and simple, it can be mounted under silos or tanks without making any mechanical modifications and without any mounting accessories.

It is compatible with most of the feet on the market and, on request, it can also be supplied with its hygienic foot.

Applications

FLC 3A has capacities ranging from 1000 to 20 000 kg and its installation is generally in groups of at least 3 load cells connected in parallel.

The 3-A Sanitary Standard certified load cells for foot are typically applied in milk cooling tanks, cisterns, reactors and tanks, in all those sectors where hygiene is a necessary or anyhow important requirement: food, dairy, chemical-pharmaceutical or leather sector.

4. Column load cells

Column load cell, COK model.

Column load cells are compression load cells whose deformable part takes on the form of a cylindrical column that shortens under load: this allows the load cell to support high loads, while keeping a limited diameter.

Applications

They are generally installed on weighbridges or on high-capacity silos, in groups of at least 4 load cells connected in parallel.

COK load cell installed in a weighbridge.

Installation of column load cells on high-capacity silos.

The Laumas range

LAUMAS column load cells are made of 17 4-PH stainless steel and AISI 4340 nickel-plated steel. They have high capacities, from 10 000 kg to 50 000 kg, but can have even higher capacities to custom design.

They have an IP68 protection rating.

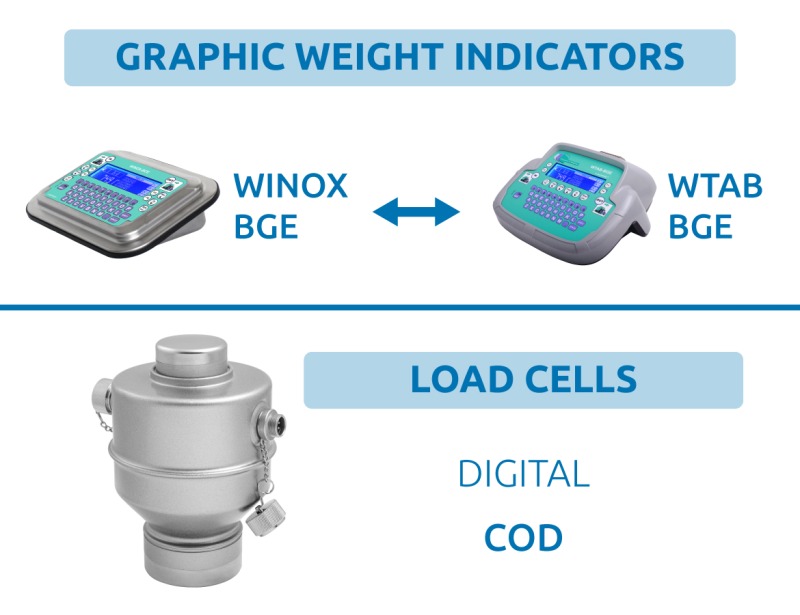

They also have a digital version with the COD model: load cells made of AISI 4340 nickel-plated steel, with an IP69K protection rating, compatible with instruments for WINOX BGE and WTAB BGE weighbridges.

For installation on weighbridges they are supplied with specific mounting accessories, while the sturdy VCOKDTL mounting kit makes installations on high-capacity silos safe.

The KITCO, KITCOK and KITCOL mounting accessories, for weighbridges.

The VCOKDTL mounting kit, for weighing silos, tanks, mixers and hoppers subject to vibration.

5. Bending beam load cells

Bending beam load cell, FCOL model.

Bending beam load cells are the simplest load cells and they work thanks to the principle of “shelf deformation”: part of the load cell has a reduced section (by means of circular or square holes) that deforms and bends when a load is applied.

The weakened part is always protected with welded covers that sometimes have a bellows shape; in this case the load cell is also called a “bellows load cell”.

Applications

Bending beam load cells are generally used for making weighing systems of small capacity such as dosing units and filling systems, bagging machines, filling machines, packing machines, small hoppers.

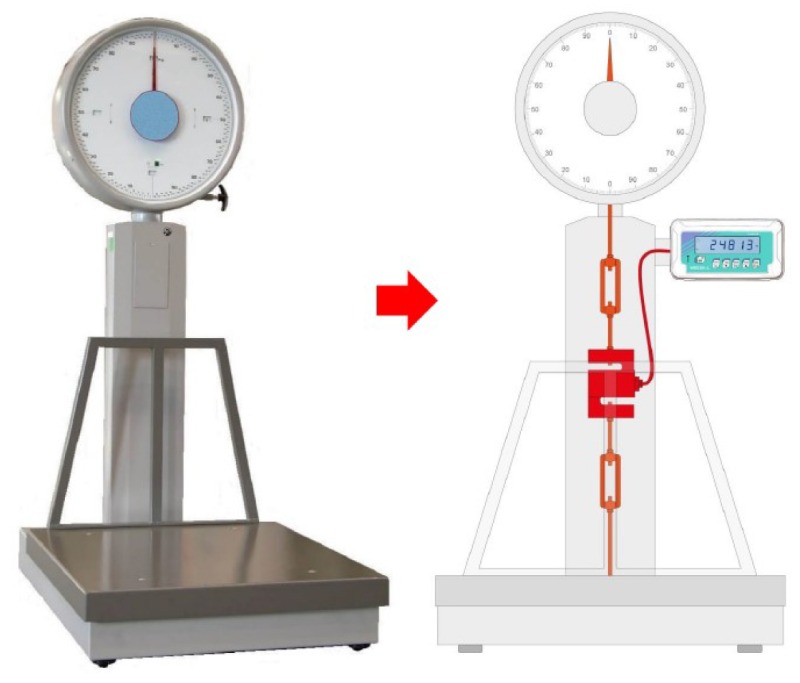

Bending beam load cells as a rule work in groups of 2, 3 or 4 load cells connected in parallel. They can also be used in single load cell applications, for example installed on the tie-beam of a mechanical scale to convert it into an electronic scale.

Single use is however less frequent and requires the force to always be applied perfectly perpendicular to the load point.

Bending beam load cell under hopper with 4 supports.

The LAUMAS range

LAUMAS bending beam load cells are made of 17 4-PH, AISI 420 stainless steel and AISI 4340 nickel-plated steel.

They have a capacity range from 5 to approximately 500 kg and protection ratings IP67 and IP68.

For this type of load cell versatility is ensured by compatibility with as many as 11 mounting kits equipped with anti-vibration and anti-tilt constraints.

When installed with an adequate complementary mounting kit, some models of bending beam load cells can work under tension in order to weigh suspended loads.

FCK bending beam load cell with a pair of STAFFECMONT stainless steel brackets for use under tension.

6. Shear beam load cells

Shear beam load cell, FT-P model.

Shear beam load cells offer very high precision and accuracy.

Their geometry is similar to that of bending beam load cells, but they differ in the “shear” technology with which the deformation is measured.

They have a plate in the middle of the hole, with an increasing thickness as the capacity increases, on which the strain gauges are glued at 45°, to maximize the rated output and minimize errors due to any rotation of the load cell.

Shear beam load cells always work under compression and depending on the type of application they can be mounted either on the frame of the structure, with the loading zone supported on the ground, or vice versa: on the ground, with the loading zone supported on the frame.

Applications

Shear beam load cells are usually used within multi load cell platforms.

They are ideal for weighing silos of small and medium dimensions, hoppers, mixers, big bag fillers and dischargers and for transport systems with belts, roller conveyors, etc.

As a rule, shear beam load cells are especially cost-effective.

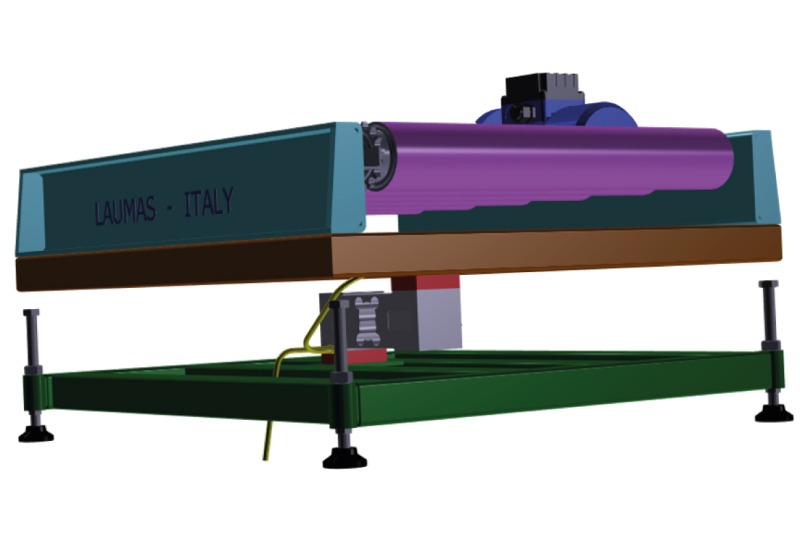

Horizontal silo supported on frame with 4 shear beam load cells.

The LAUMAS range

LAUMAS shear beam load cell models are made of 17 4-PH or AISI 420 stainless steel and AISI 4340 or AISI 4140 nickel-plated steel.

They have medium-high capacities, from 300 kg to 10 000 kg and protection ratings IP67, IP68 and IP69K.

They are very versatile, also because they are supported by as many as 9 different mounting kits which, depending on the application, can have anti-vibration or anti-tilt functions.

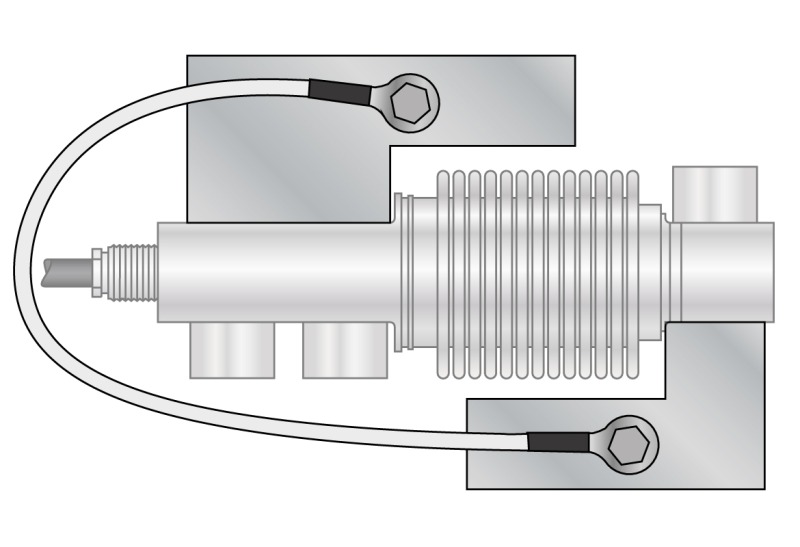

For applications requiring very accurate weighing, in addition there is the complementary mounting kit ACCSFER, composed of a ball through which the force is transmitted without any friction and therefore with the greatest repeatability and precision.

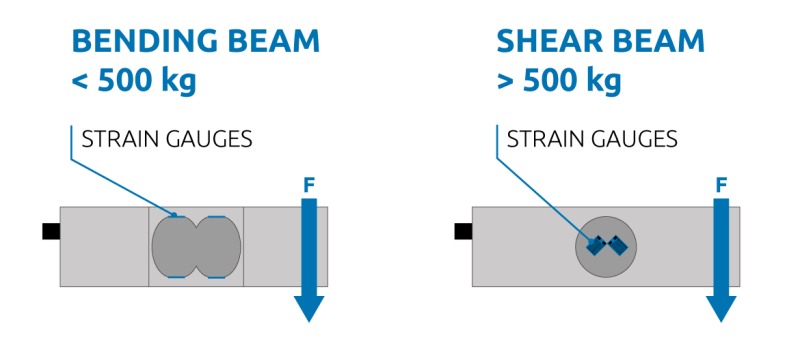

Some LAUMAS load cell models (FCAX, FTP, FTK) are available in two different versions: bending and shear.

Although being built with the same form and the same material, they differ in the application of strain gauges and in capacity:

-

in the bending versions the strain gauges are fitted horizontally and the capacities are under 500 kg;

-

in the shear versions the strain gauges are fitted vertically and the capacities range from 500 kg up to 10 000 kg.

7. Tension load cells

Tension load cell, CTL model.

When the loads to be weighed have to be suspended tension load cells are used.

They are special shear or bending beam load cells, depending on the capacity.

Thanks to their various options, they can be fitted on all tension force measuring systems, through threaded fasteners or with the classic lifting eyebolts/shackles.

Example of CTL tension load cell used in a crane scale.

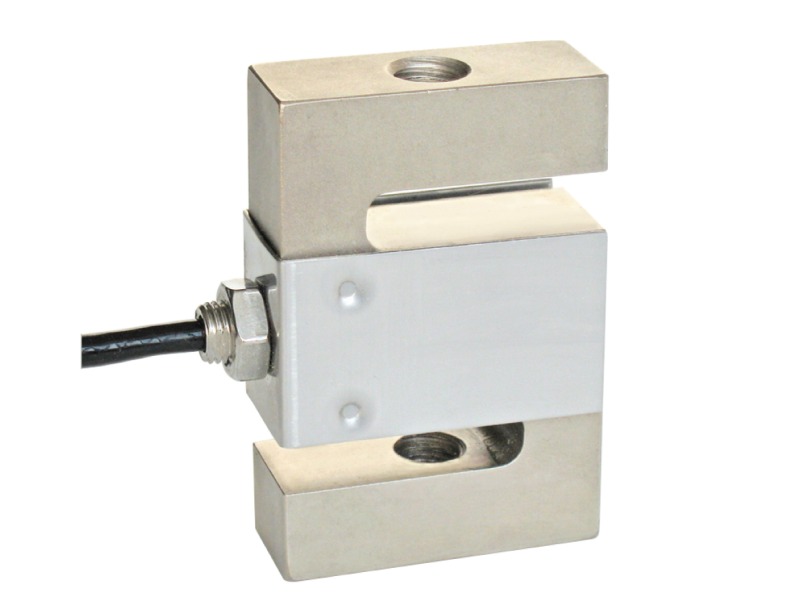

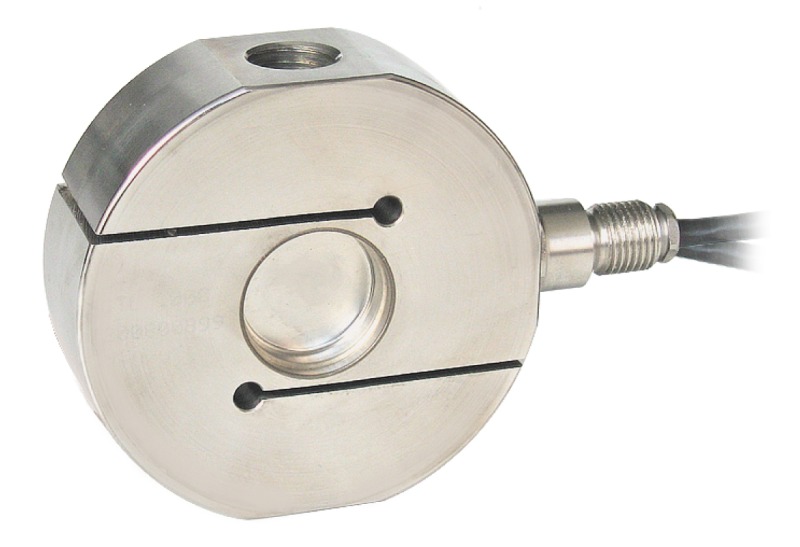

S load cell, SL model

Some models of tension load cells are, due to their shape, also called “S load cells”.

Although in most cases they are used in applications in which they work under tension, they can also work under compression.

Applications

S tension load cell, applied on the tie-beam of a mechanical scale to digitize it.

Tension load cells are used both individually and in groups connected in parallel.

They are used in suspended weighing systems such as bridge cranes, cranes, lifting machines, overhead platforms, crane scales, but also in hoppers, weighing belts and concrete mixing systems, or to transform old mechanical scales into electronic scales (revamping).

Concrete mixing system: weighing aggregate on belt suspended on tension load cells.

The LAUMAS range

LAUMAS tension load cells are made of 17 4-PH and AISI 420 stainless steel and AISI 4140 and AISI 4340 nickel-plated steel.

They have IP65 and IP69K ratings for protection against jets of water; IP67 and IP68 for protection against immersions.

They cover a very broad capacity range: from 15 kg up to 250 000 kg.

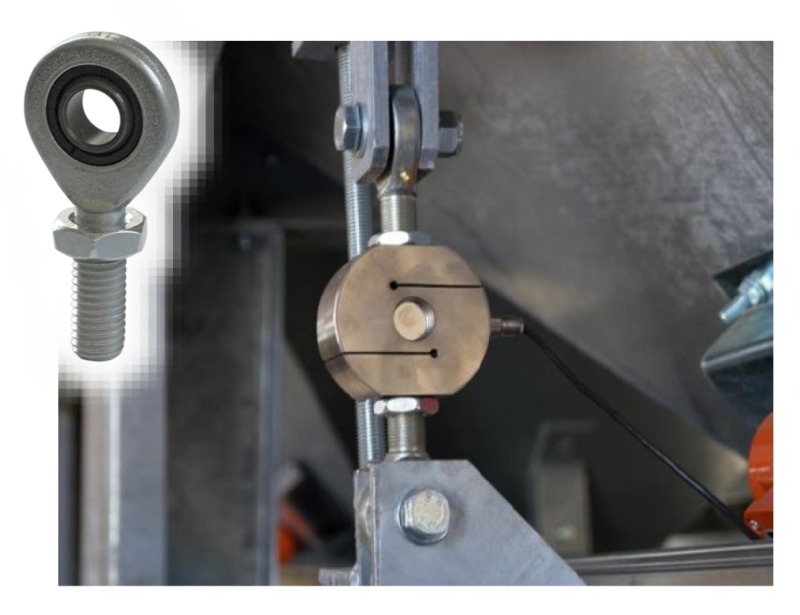

For medium-low capacity models there are ball joints with a nut (EM – DADO), eyebolts that allow the load cell to always work torque-free, thus avoiding both weighing errors and potential damage to the load cell itself.

CTL tension load cell with 2 ball joints EM – DADO

Since tension load cells are used also as load limiters in weighing suspended loads, for reasons of safety we recommend in any case always having structural devices that can intervene in the event of mechanical breakage of the load cells due to improper use or accident.

Tension load cell, TAL model, with safety device.

In the event of an electrical fault, instead, safety is ensured by the option of having two redundant strain gauge Wheatstone bridges with two output cables, for double safety systems.

CTL tension load cell with two output cables for dual safety redundant systems.

This solution is a legal requirement in certain weighing and load limitation applications, such as lifting people (for example on overhead platforms), but the customer may also choose it whenever there is the need to ensure continuous operation of an application also in the event of one of the two weighing systems malfunctioning.

This option is also available for pin, shear and compression load cells.

8. Compression and tension load cells

Compression and tension load cells, CL and CLBT models.

Compression and tension load cells are special versions of compression load cells that can also measure forces of tension thanks to the fixing holes and threaded loading zones.

There are, in fact, models with a central thread (male) and others with a hole in the middle (female).

A force is applied onto the threaded pin or hole, both under tension and under compression, while the holes on the outer crown permit fixing the load cell to the structure.

There are two types of compression and tension load cells:

- diaphragm, if the strain gauges are glued onto the deformable diaphragm;

- Spoke load cells are normally composed of 4 or more spokes that behave like independent shear beam load cells, making the sensor especially accurate and precise.

Applications

They are used both individually and in groups, connected in parallel.

The most common applications are: material test machine, tests in the field, quality control machines and presses.

Pair of CL load cells applied on tyre test machine.

The LAUMAS range

LAUMAS compression and tension load cells are available in aluminum alloy, 17-4 PH stainless steel or AISI 4340 nickel-plated steel; with IP65, IP67 and IP68 protection ratings.

The standard capacities range from 50 kg to 200 000 kg, but with some custom versions we have reached up to 500 000 kg under compression and 250 000 under tension.

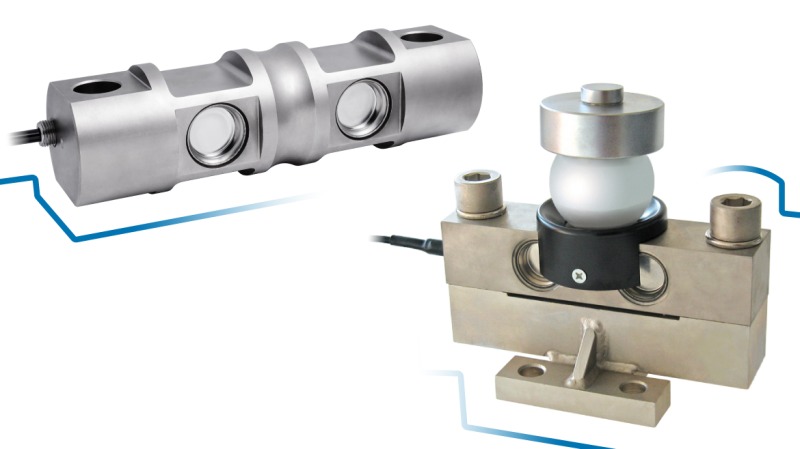

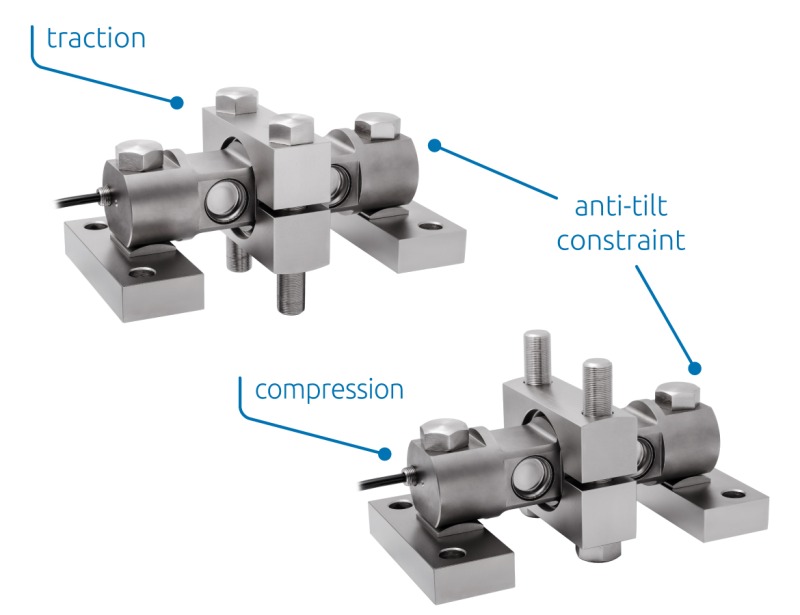

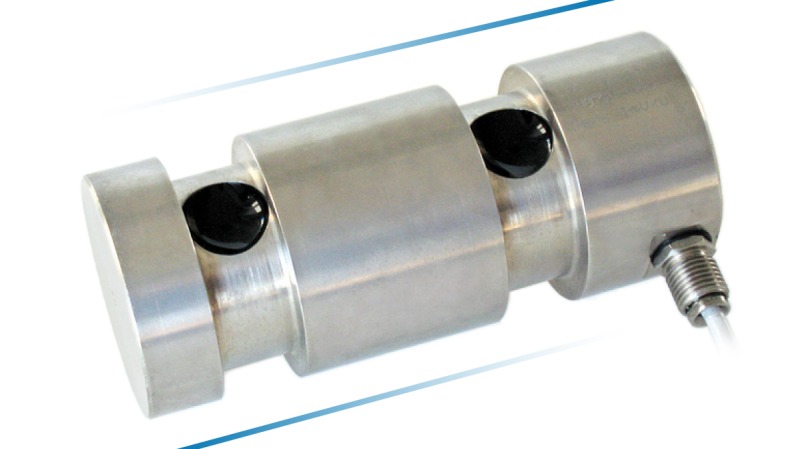

9. Double shear beam load cells

The double shear beam load cells DTL and DTX.

Double shear beam load cells are a special and particularly precise and accurate version of shear beam load cells, characterized by symmetry in relation to the load point. They are, in fact, designed to be secured at both ends and loaded in the middle.

This symmetry improves load cell performance and ensures a certain insensitivity to any lateral forces, making them suited also to special uses.

Applications

DTX load cell used in weighing a load body on board a vehicle.

Double shear beam load cells besides being especially precise and accurate are also sturdy, suitable for weighing high loads.

They are typically used in weighbridges, on-board weighing for vehicles and high-capacity silos, even installed outdoors.

The LAUMAS range

LAUMAS offers two models of double shear beam load cells, both made of AISI 4340 nickel-plated steel and with an IP68 protection rating.

The high capacity ranges from 9000 kg to 27 000 kg.

As regards the most appropriate mounting kits:

- for weighing high-capacity silos the combination of the DTL load cell and the sturdy VCOKDTL is perfect;

- for making high-capacity weighing systems approved for legal for trade use and for on-board weighing for vehicles, the OIML R 60 approved double shear beam load cell DTX together with the very compact and strong VDTX mounting kit, is ideal.

The VDTX mounting kit in its 2 uses: tension and compression.

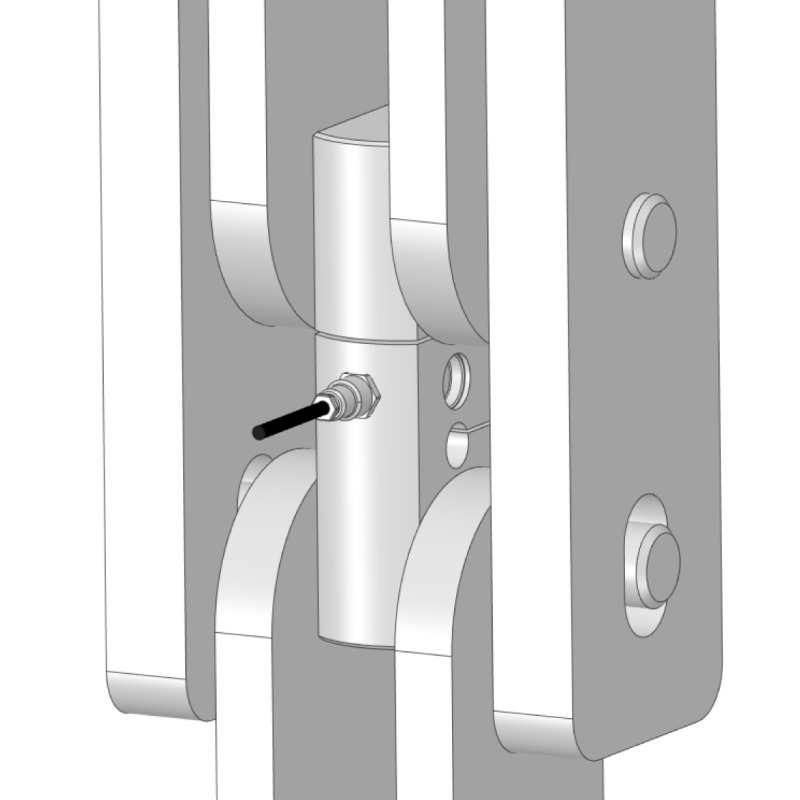

10. Pin load cells

LAU pin load cell.

Pin load cells are special types of double shear beam load cells (more rarely also shear beam load cells, depending on the assembly needs).

They provide precise and accurate performance and have a high safety coefficient, required by the lifting systems in which they typically act as load limiters.

The safety coefficient is a design value that increases the yield point and strength of the load cell: the applied load being equal, pin load cells undergo much less deformation than standard ones and have a breaking load that is generally at least 5 times the rated capacity.

Applications

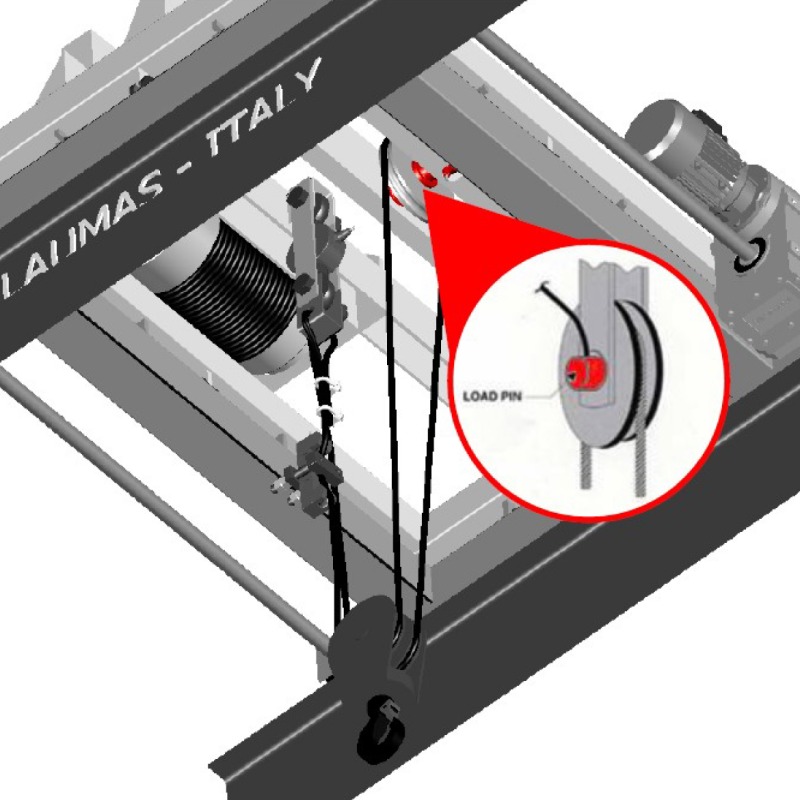

Pin load cell on a pulley in a lifting system.

Pin load cells are applied in lifting systems on a fixed end or pulley (such as a bridge crane and crane).

They are often used to complement a load limitation or weighing system on an existing structure, without any modification or impact on it: they are installed in place of generic pins already installed without a measuring function, with which they are easily interchangeable.

The LAUMAS range

Pins always have different dimensions so as a rule LAUMAS makes custom pin load cells, to the customer’s custom design.

A standard model is also available in the catalog: LAU.

LAU is made of 17 4-PH stainless steel, with capacities from 5 000 to 20 000 kg and protection rating IP67.

Some examples of custom pin load cells made.

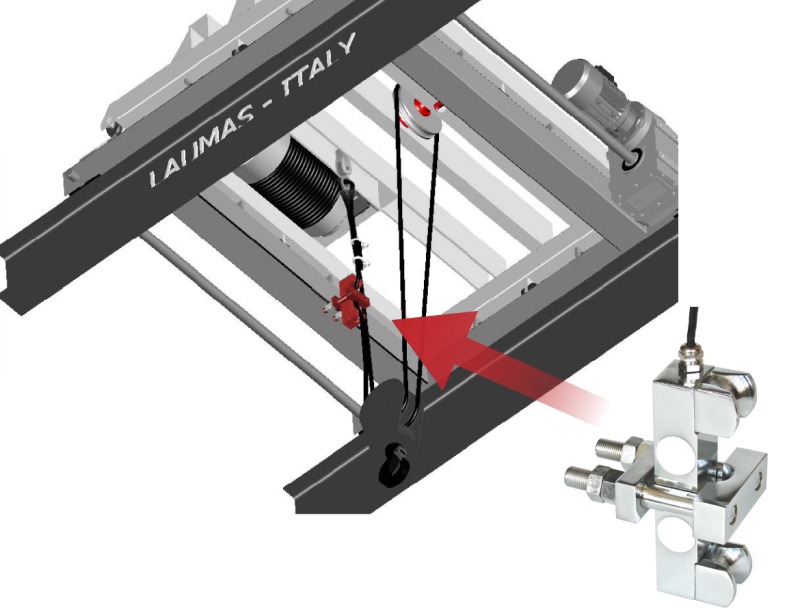

11. Load cells for wire rope measuring

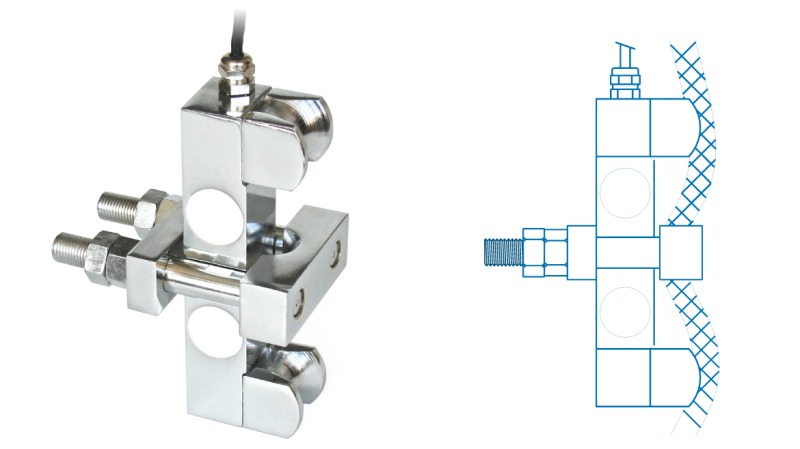

The FUN load cell for wire rope measuring.

Load cells for wire rope measuring are a special type of double shear beam load cells, whose geometry allows them to be perfectly coupled with the most common models of rope, without altering the installation.

Because of the specific type of assembly directly on the rope, even if they are double shear beam load cells, accuracy and precision are reduced. Normally, however, these load cells are only used as load limiters in applications that do not especially need these characteristics.

Accuracy and precision in any case greatly depend also on the stiffness of the rope, related to its density, determined in its turn both on the type of wire and on the dimensions and number of strands.

A strand is a set of single wires woven together. A rope is composed of a number of strands wound together on a central core.

Applications

Load cells for wire rope measuring typically work individually as load limiters for bridge cranes and cranes.

FUN load cell applied on a bridge crane as a load limiter.

The LAUMAS range

The load cell for wire rope measuring offered by LAUMAS is called FUN .

It is made of AISI 4140 nickel-plated steel, with an IP67 protection rating.

It is available with capacities from 2000 to 40 000 kg and supports ropes with a diameter from 6 to 36 mm.

FUN is very easy to install: it is applied like a clamp on the rope, directly under the fixed end, without any mechanical changes to the system.

The load cell is not recommended for precision weighing, but is always used only as a load limiter.

It is very safe: there is no obligation to have an additional safety device because it does not have a structural function, so in the event of mechanical breakage there are no consequences for the system.

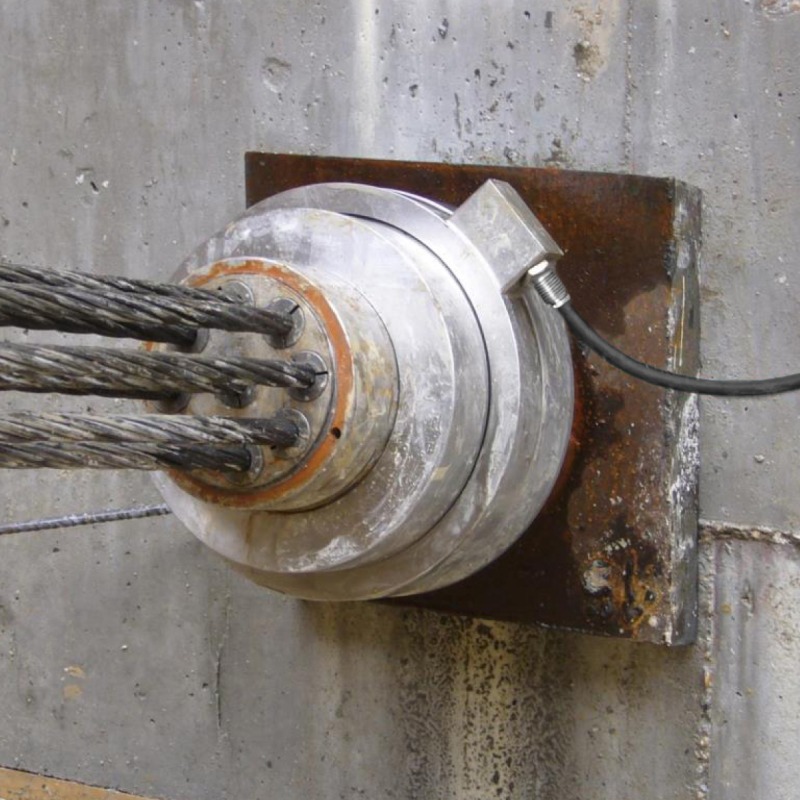

12. Anchor load cells

Anchor load cell, CA model.

Anchor load cells, also called “toroidal load cells” or “ring load cells”, are used above all in monitoring systems or for measuring the forces transmitted or sustained by shafts.

They are diaphragm load cells where the diaphragm has reduced radial dimensions in order to leave room for housing tie-beams and shafts.

Applications

Anchor load cells are installed to measure and monitor the tensioning force of tie-beams in civil works such as dams, bridges, tunnels and retaining structures.

They perform this measuring function both at the testing stage and over time in order to detect any significant changes in the force and prevent any structural yielding.

The LAUMAS range

The LAUMAS anchor load cell is called CA, is made of 17-4 PH stainless steel, with capacities from 30 000 to 250 000 kg, and has an IP68 protection rating.

It can be supplied with specific plates for load distribution: corrected plates made of galvanized steel that allow the load cell to be supported perfectly and therefore distribute the load evenly along the entire circumference.

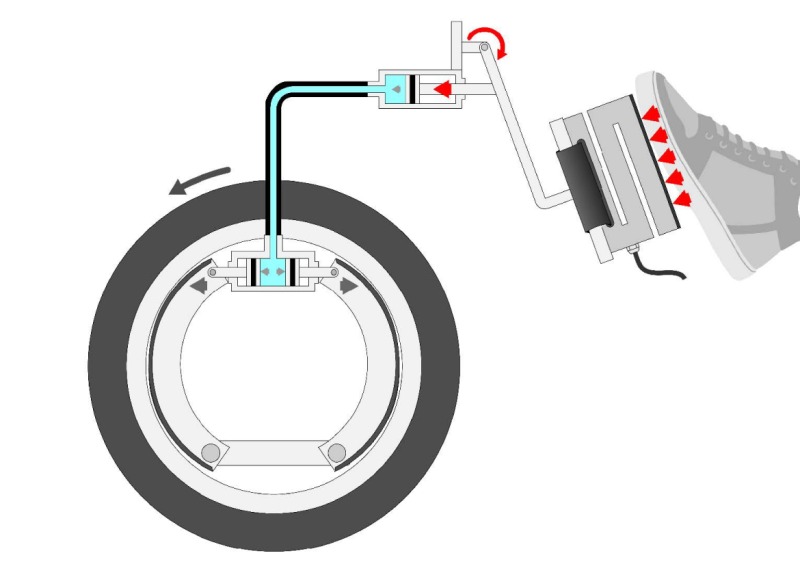

13. Load cells for foot brake

The LPED load cell for foot brake.

Load cells for foot brake are a pocket-sized, hand-holdable variation of bending beam load cells, specific for testing thrusts applied by a user.

Applications

A typical use is to measure the force exerted by the foot on a car’s brake pedal, to which the load cell is fixed with Velcro.

They are widely used also to measure the forces applied manually by workers on car bodies, chassis and styling of vehicles and machinery, but also to simulate agents of external forces.

The LAUMAS range

LAUMAS offers the LPED model, made of aluminum, with an IP65 protection rating and a single capacity of 100 kg, ideal for the specific application for which the load cell is intended.

14. Custom load cells

When it is not possible to use a standard load cell to resolve issues of weighing and measuring in particular situations, it is considered whether to make a custom load cell, to the customer’s design and therefore for unique, specific requirements.

The LAUMAS range

LAUMAS custom load cells besides being designed with special mechanical dimensions can:

- be biaxial, triaxial and also measure torque;

- be pre-amplified;

- have two strain gauge Wheatstone bridges for redundant dual safety systems;

- have non-standard thermally compensation (-30° / +70°) and special high/low temperature cables;

- be ATEX and IECex certified

FOCUS:

Which types of load cells have the longest life cycle?

The life cycle of a load cell depends on how many work cycles a load cell can withstand during its working life.

The work cycle of a load cell is completed each time a load cell is taken from 0 to full scale.

Shear beam and compression load cells reach approximately 8 million

work cycles. Bending beam load cells instead reach approximately 4 million.

LAUMAS has also built custom load cells that can reach up to 100 million cycles.

Load cells that reach up to 100 million cycles are also said to have “high fatigue resistance”.

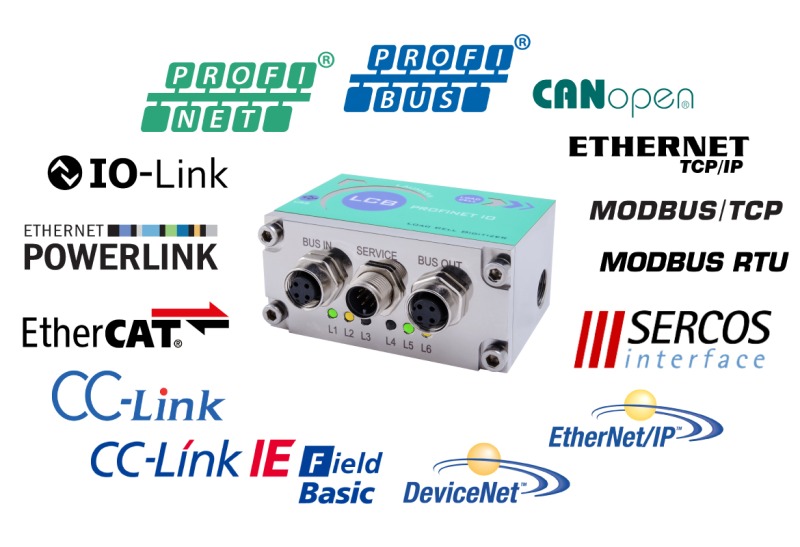

15. Universal digitizers for load cells

LCB Profinet integrated on the CL compression and tension load cell.

Depending on the type of signal transmission, load cells can be digital or analog.

Digital load cells have integrated electronics to process the measurement results and present them in a set format.

Analog load cells instead have to be connected to a weight transmitter or a weight indicator.

LAUMAS has conceived an innovative proposition: the LCB universal digitizers for load cells, very compact weight transmitters that wired and screwed directly onto any load cell with analog output, transform it into a digital load cell.

There are 3 versions:

- LCB: classic stainless steel version and cheaper plastic versio

- LCB3A - hygienic version certified 3-A Sanitary Standards

The LCB digitizers are conceived for a totally integral assembly with the body of the load cell, but can also be installed on the wall.

All LCBs can be configured and managed from a PC using the free Instrument Manager software and they connect to the PLC via the most popular field buses (Profinet IO, EtherNet/IP, Ethernet TCP/IP, Modbus/TCP, Modbus RTU, Profibus DP, EtherCAT, POWERLINK, CANopen, CC-Link, Sercos III, IO-Link , CC-Link IE Field Basic)

→ Read also: How to choose a load cell? Technical features guide

→ Read also: How to choose a load cell? The factors to assess

RELATED PRODUCTS

AZL

Single point load cells

CBL

Compression load cells

CL

Compression & Tension load cells

COD

Digital load cells

COK

Column load cells

CTL

Tension load cells

DTL

Double shear beam load cells

FCOL

Bending beam load cells

FLC 3A

Compression load cells

FT-P

Shear beam load cells

FUN

Load cells for wire rope measuring

LCB

Load cells digitizer

SL

Tension load cells